Consequences of the pandemic, supply bottlenecks, the Medical Device Regulation and a multitude of innovations all result in an agenda full of exciting topics

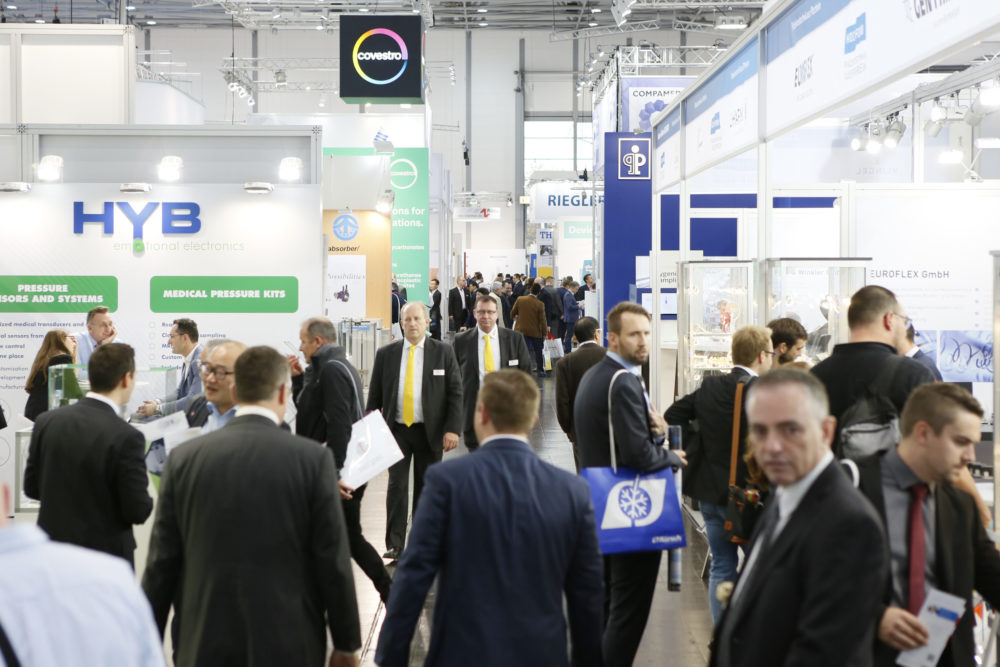

After COMPAMED, the international leading event for suppliers of medical technology, could only be held digitally due to the pandemic last year, it will now be held in-person again at Messe Düsseldorf from 15 to 18 November, at its fixed runtime in parallel with the world leading medical trade fair MEDICA. Almost 500 registrations from exhibitors prove that there is a high level of interest from medical technology suppliers, which is a huge step towards reaching normality again. In accordance with the hybrid event concept, significant programme components such as the COMPAMED HIGH-TECH FORUM from the IVAM International Microtechnology Business Network which specifically focuses on the microtechnology and nanotechnology sectors and the COMPAMED SUPPLIERS’ FORUM from Devicemed, which covers the entire development and production sector in medical technology, will be offered as both online (as a live stream) and in-person events which can be accessed by purchasing the relevant ticket. In contrast to the previous years, COMPAMED will be held in Halls 13 and 14 this year (instead of Halls 8a and 8b). By moving the event to new halls, Messe Düsseldorf is meeting the wishes of the federal state government of North Rhine-Westphalia, namely to ensure that they can continue to use the north area of the trade fair centre for activities in conjunction with the COVID-19 vaccination campaign.

Both the omnipresent COVID-19 pandemic and its consequences will provide much food for thought: “Due to the impact of the corona crisis, supply bottlenecks have occurred: flight and seaborne transportation cancellations have led to huge supply bottlenecks, particularly for electronic products. During the crisis, this was exacerbated by unnecessary stockpiling. Companies bought and stored more components than they needed to ensure that they were safe because they were scared of experiencing a shortfall in supply”, explains Dr. Thomas R. Dietrich, CEO of the IVAM International Microtechnology Business Network. Raw materials and individual components were also scarce, because the industry recovered more quickly than many suppliers expected it to. However, this will return to normal within a short period of time.

Computer chips were in short supply during the crisis because medical technology suppliers in particular suddenly needed far more of them. Dr. Meinrad Lugan, CEO of BVMed, recently put the situation into perspective: In many sectors, the issue was not shortages in terms of quantity, but instead distribution issues. Lugan notes that there was a “trend to make huge excess orders or multiple orders”. The resulting supply bottlenecks should be combated using “smart digital solutions based on existing eStandards”. According to IVAM, internationalisation of the economy would still be expedient, as the global supply chains could not be maintained, which is the opposite of constructive. European manufacturers need the option to carry out production at a lower cost in other countries in order to remain competitive. These producing countries, in turn, need European customers in order to keep their own economies running. According to IVAM, there should, however, still be local supply chains for critical components – particularly for sensitive products that are important for basic care of the entire population, e.g. in the healthcare sector.

One topic continues to cause a huge stir...

Another topic also triggered huge upheaval in the industry: On 26 May 2021, the new European Medical Device Regulation (MDR) and the equally new Regulation on In-Vitro Diagnostic Medical Devices (IVDR) came into force. As the long-read overview article on this subject in the Devicemed trade magazine states, the companies are prepared to take this on but are also clearly under pressure. According to a survey from the software company Climedo Health, 81% of the 115 companies surveyed from across Europe still find the MDR very challenging. The biggest hurdles are presented by an increase in the resources and costs needed, a lack of clarity and the requisite clinical testing. 31% estimate that the MDR will cause additional costs of 5 to 10% of their annual turnover to be levied, and 13% believe that these costs will amount to over 10% of their turnover. The companies’ dissatisfaction with the powers that be in Brussels is also mounting in other aspects: 75% wish for clearer specifications from the EU Commission, 50% want more specialist support and 30% want training or information events. “The survey results show that the EU MDR continues to be very challenging, expensive and time-consuming for companies”, states Veronika Schweighart, COO at Climedo Health. The IVDR also increases effort and costs for companies. Along with new products, all approved products which are already available on the market need to undergo recertification in accordance with the regulation. In addition to this, the notified bodies must be put through a new notification procedure, which has not yet been finalised. Furthermore, the IVDR encompasses a greater scope of application than the previous directive and, in many areas, brings in more stringent and also new requirements for companies and monitoring bodies. This will result in much matter for discussion within the scope of COMPAMED 2021.

The Medical Device Regulation: as tough as cold fusion?

The COMPAMED SUPPLIERS’ FORUM (in Hall 14) also picks up on this topic in its series of talks. “Often, when dealing with the MDR or the IVDR, one has the impression that we’re working on cold fusion or rocket science. The basics for all of the points stated above are lacking. I cannot yet say which of the three topics will be resolved first, but we can all be better informed on the MDR and IVDR, at the least. There were many difficult aspects, but there are themes that are resolved well – complicated guidance, which is a contradiction in itself, and clever solutions”, summarises Stefan Bolleininger, CEO of the consulting firm be-on-quality. His talk (on 17 November) delineates concrete examples from his consulting practice and options for solving various problem scenarios. This concerns, for example, the handling of non-harmonized standards or what is considered to be state of the art.

Current developments throughout the entire process chain

The COMPAMED SUPPLIERS’ FORUM has even more to proffer in terms of content. Current developments throughout the entire process chain will be presented in a hands-on manner: mechanical and electronic components have their moment in the spotlight in the expert talks, along with innovative basic materials, manufacturing processes, all types of contract manufacturing, design and usability aspects and quality assurance. Keynote speeches on new markets complete this diverse programme. Further focal themes include the additive manufacturing, electronic and regulatory affairs sectors.

Thus, Dr. Benedikt Janny, who is the Managing Director of USE-Ing. and Head of the User Research and Usability Engineering Division there, reports on human-centred development of medical technology products, better known as usability engineering: This is not only a regulatory obligation for medical device approval, but also offers medical device manufacturers the opportunity to differentiate themselves on the market by taking relevant user wishes into account early on in the product development process and implementing them in the innovations. The keynote speech (on 15 November) explores which regulatory requirements are applicable for usability engineering and the opportunities that exist to establish human-centred development processes and to create actual added value for the product user by increasing usability within the scope of user-centred innovations. The usability engineering process is closely linked with quality management and the requirements engineering process. In addition, Dr. Janny, as an expert, will indicate which types of use-based risks exist and are to be analysed within the course of the product development process. In addition, the question of which prototypes companies can generate without great cost and effort in order to validate their medical products early on with real users is also explored.

Additive manufacturing for custom implants for patients

Additive manufacturing and robotics remain exciting themes in medical technology. Toolcraft AG sees itself as a pioneer of future-oriented technology such as additive manufacturing and in the construction of individual robot cells. As a partner for complete solutions, the company offers the entire process chain, from the concept to manufacturing to qualified precision components using additive manufacturing, machining and injection moulding, electrical discharge machining and mould making. Within the scope of robotics, customised, fully programmed integrated solutions are implemented. Daniel Distler and Patrick Meyer (Head of the Robotics Division and Head of Technical Sales and Distribution at Toolcraft) put their knowledge from over 30 years of experience in the industry to good use in their talk (on 15 November) at the COMPAMED SUPPLIERS’ FORUM and detail the advantages of additive manufacturing using a wide variety of appliecation cases for medical technology. For example, Toolcraft AG uses additive manufacturing to make custom implants for individual patients. Furthermore, this mid-sized company has developed an automated complete solution for manufacturing and packaging a cerumen filter for hearing aids (which protects against contamination with ear wax and moisture).

Holger Frank, CEO of Mechatronic, has selected the theme “The potential of the IoT in medical technology – using the example of the AED” for his forum speech (which is also on 15 November). An AED is an automated external defibrillator, a portable medical device that can also be used by people without medical training. “In terms of the future development of important IT technology, 80% of all those surveyed assume that the Internet of Things will play an important role, according to a study by PwC”, explains Frank. Mechatronic delivers important devices for IoT developments in the medical field which enable communication between the device and the cloud. In essence, two solutions are possible: the device and communication are either integrated into one system or into separate units. An important factor for all versions is the question of which radiocommunication standard they need to be certified with. These vary throughout Europe and the USA and also differ based on the country one is based in. Large countries such as China, Russia and Canada also have their own standards. Mechatronic emphatically pleads the case for AEDs that execute an automatic test every day and has developed the relevant hardware to enable the test state to be monitored via a cloud solution. The background for this is that around 30% of the devices which are available in public space do not work because the maintenance and servicing have not been carried out correctly.

The many highlights of IVAM in Hall 13

The IVAM International Microtechnology Business Network is once more one of the cooperation partners for and biggest exhibitors at COMPAMED. This year, 42 companies and institutes from nine nations are present on the joint stand (in Hall 13), with many hailing from Europe. The technology being represented includes diverse microcomponents (microelectronics, optronics, microoptics, microfluidics), sensors, actuators and sensor systems, micropumps, coatings, smart textiles and manufacturing and processing procedures, along with services. The COMPAMED HIGH-TECH FORUM (also in Hall 13) offers international presentations in accompaniment to the trade fair on each day of its four-day run and will present a wide range of themes in 2021 too. These include, in particular, printed electronics and highly integrated diagnostics for the next generation, “Equipment manufacturer meets component manufacturer”, laser and photonic applications, smart sensor solutions and microfluidic options to resolve challenges in point of care diagnostics and the life sciences.

Measuring blood pressure with an optical sensor

Highlights on the IVAM stand include new sensory developments. Conditions involving the cardiovascular system are among those which are most frequently cited as a cause of death in the industrialised nations. An important indicator for this is high blood pressure, which is currently still diagnosed and monitored by regularly taking blood pressure mechanically using an upper arm cuff. This method is uncomfortable and limits the patient in their daily activities, and, in comparison to other methods, only delivers a few selective measured values. An optical sensor can provide help here. This sensor, which works using the basic principle of photoplethysmography (PPG), records the fill level of the blood vessels in the skin over time. Using the contour curve (pulse waves) recorded in this manner, a patented procedure is used to identify relevant points in time to determine the cycle of the pressure wave in the aorta, which enables conclusions to be drawn on changes in central blood pressure. In addition to offering an alternative to classic cuff measurement, the process also gives a blood pressure result for each individual heartbeat. With this analysis of short-term and mid-term fluctuations, doctors expect to achieve a novel diagnostic approach for early detection of a variety of conditions in multiple different patient groups (e.g. pre-eclempsia). The sensor developed at the CiS Forschungsinstitut für Mikrosensorik (CiS Research Institute for Microsensors) can be worn in the ear, which, in addition to numerous physiological advantages for signal quality and signal stability, means that it is comfortable to wear throughout the day. In addition to blood pressure, it can record many other vital signs such as heart rate, heart rate variability and blood oxygen levels.

Within the scope of the COMPAMED HIGH-TECH FORUM, Dr. Martin Schädel, Head of the MOEMS Division at the CiS Forschungsinstitut für Mikrosensorik, will give a lecture on this development

High-tech communication between the body and modern IT

With its next-generation electrode design, CorTec creates new pathways for communication between the body’s own electric signals and modern information technology. This young medical technology company specialises in developing efficient technology for active implants for recording over long periods of time and stimulation of neuronal activity. The technology comprises customised components such as electrodes for derivation and stimulation within the central and peripheral nervous systems. Its patented AirRay electrode technology has enabled CorTec to overcome the current limitations when working with electrodes with mechanical properties that can be adapted flexibly and highly precise manufacturing conditions. The manufacturing process, using ultrashort pulse lasers, makes the technology highly reproducible even at very small dimensions of as little as 25 μm, and with a high density of electrical contacts. The flexibility of the technology enables a wide variety of product properties, such as thickness, the number of contacts, contact spacing and contact shape, and the total size of the electrode, to be modified.

The components can, for example, help localise the epileptogenic focus that needs to be removed using surgery in patients with certain types of epilepsy . CorTec’s aim is to be a leading partner in developing innovative therapies. In particular, the design flexibility of the AirRay electrode technology makes it into an important building block for the approach of communicating with the human nervous system and connecting it with artificial intelligence. This special electrode technology is, like the ceramics-based hermetic encapsulated casing, part of the CorTec Brain Interchange, a technology platform for innovative neurotherapy in a variety of fields of application such as epilepsy, Parkinson’s disease or bioelectronic medicine.

A world first for stoma care

Optima Life Science and Optima Automation will present a world first when they participate in COMPAMED 2021 together – the first continuous manufacturing machine for stoma flanges. These are used as care products for artificial openings used to divert waste from the intestines (stoma). Thus, Optima Life Sciences now also offers an appropriate machine solution for stoma producers. The main advantage is that it brings two separate converting processes together in one line. Process stations that could previously only be operated in cycles were developed for this line.

Innovative microtechnology that serves the pharmaceutical industry

Another example of high-tech that conclusively demonstrates the expertise of the COMPAMED exhibitors are the micro annular gear pumps from the manufacturer HNP Mikrosysteme. Microencapsulation is also growing in significance in the pharmaceutical industry. Precise dosing techniques which can dose miniscule quantities are a prerequisite for manufacturing and processing APIs (Active Pharmaceutical Ingredients). Manufacturing these APIs is demanding as these substances, which can be anywhere on a scale from watery to oily, need to be handled very delicately. Microencapsulation is the perfect procedure to protect these active substances from premature release and thus preserve their biological activity. The capsules are made of polymers or inorganic material. Depending on the permeability and degradability of the capsules, the active ingredients are released at a gradual rate. A continuous release makes therapy with medication easier to tolerate and simpler to handle. The delivery rates of the quantities range from a few microlitres per minute to 140 ml/min. The precision of the delivery rate is crucial for the quality of the capsules; the tolerance for this is only plus/minus one percent. Micro annular gear pumps from HNP Mikrosysteme are used for this challenging task. The pumps can be heated or can be fitted with an additional reduction gear for the smallest quantities.

All information on COMPAMED 2021 regarding the companies taking part and their products, integrated forum programs and more is available online at: https://www.compamed-tradefair.com.

Dates for COMPAMED 2021 + MEDICA 2021: 15. - 18 November

Opening times: 10:00 am to 6:00 pm

Author: Klaus Jopp, freelance technical writer for science and technology (Hamburg)